Unique low cost alarm/indicator panel for use with any 4B NTC-type temperature sensors. ADB810, WDB70, and WDB810 series sensors are recommended.

The T400N ELITE is able to accept signals from up to 8 NTC sensors (zones), which are separated into two groups of 4 zones. Each group of sensors is able to cause alarm and shutdown of individual machine when hazardous conditions are detected. There is a total of 2 Alarm and 2 Stop relays. The control unit is housed in a self contained wall mounting enclosure. A test push button on the lid of the control unit provides for full system verification. Alarm and status LEDs provide means of quick location of the alarm condition, and voltage free relay contacts provide separate alarm and shutdown control. An alarm mute push button is provided on the lid of the control unit and additional connections are provided for an external alarm mute functionality. A rotary switch is used to select the temperature alarm value.

- Monitors up to Eight Temperature Zones

- Can Monitor Two Separate Machines via 2 x Alarm and 2 x Stop Relays

- Selectable Alarm Temperature Level

- Configurable Alarm and Stop Delays

- LED Alarm Indication and Power Status

- Alarm Mute - Automatic Reactivation on New Alarm

- Test Feature – Externally Controlled Test Facility

- Dust Hazard Approved

Belt Conveyor

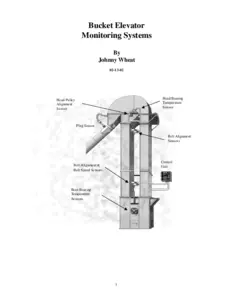

Bucket Elevator

Chain Conveyor

Screw Conveyor

Specifications

Part numbers:

- T4004NV4CAI - T400 NTC Elite Control Module - 24 VDC; ATEX and IECEx Zone 21 and Zone 22

- T4004NV46CAI - T400 NTC Elite Control Module - 110-240CAV 50/60Hz or 24VDC ATEX and IECEx Zone 22

Options / Accessories:

- TX400PLCB PLC Relay Board with 8 relays

- NTC Bearing Sensors (Type WDB or ADB )

Technical Specifications:

| T4004NV4CAI | T4004NV46CAI | ||

| Input Supply Voltage | 24 VDC (T4004NV4CAI) | 120 to 240 VAC or 24 VDC (T4004NV46CAI) | |

| Alarm Relay Contacts | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | |

| Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | ||

| Stop Relay Contacts | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | |

| Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | ||

| Sensor Inputs | Up To 8 NTC Thermistors | Up To 8 NTC Thermistors | |

| Sensor Supply | 24 VDC - 100 mA Maximum | 24 VDC - 100 mA Maximum | |

| Terminals | Power: 4 mm^2 - 14 AWG Maximum | Power: 4 mm^2 - 14 AWG Maximum | |

| Signals: 2.5 mm^2 - 16 AWG Maximum | Signals: 2.5 mm^2 - 16 AWG Maximum | ||

| Dimensions (H x W x D) | 9.7 x 7.4 x 4 (inches) / 246 x 188 x 102 (mm) | 9.7 x 7.4 x 4 (inches) / 246 x 188 x 102 (mm) | |

| Fixing Centres (H x W) | 8.75 x 4 (inches) / 222 x 102 (mm) | 8.75 x 4 (inches) / 222 x 102 (mm) | |

| Cable Entry | 2 Holes x 25mm Dia | 2 Holes x 25mm Dia | |

| Weight | 3 lbs / 1.3 Kg | 3 lbs / 1.3 Kg | |

| LED Status Indicators | Green LED - Power | Green LED - Power | |

| Green LED - Hot Bearing #1 through #8 | Green LED - Hot Bearing #1 through #8 | ||

| Red LED - Alarm | Red LED - Alarm | ||

| Push Buttons | Mute | Mute | |

| Test | Test | ||

| WARNING | WARNING |

Downloads

Sensors

ADB Series Bearing Sensors

The ADB series have been designed to allow the depth of the sensor to be adjustable depending on your application. A number of versions are available with probe lengths of 50, 100, 200 and 300 mm. The sensors screw directly into a bearing housing through a 1/4” BSPT threaded grease zerk. Each sensor is fitted with a grease zerk to allow lubrication of the bearing without the need for removal of the sensor. The ADB series have NTC or PT100 type thermistors which allow for continuous temperature monitoring.

The sensor is supplied with a 3m attached cable and can be connected to a PLC or to a hazard monitoring system, such as 4B’s Watchdog Super Elite, T500 Hotbus Elite or T400 NTC Elite. The connections are not polarity sensitive therefore special connection requirements are eliminated, and the cable can be extended in the field.

WDB7 Lug Style Bearing Sensors

The WDB7 series is a lug style NTC thermistor or platinum RTD (PT100) type for continuous temperature monitoring. It is designed to bolt directly onto a bearing housing, motor, gearbox, or machine casing. The mounting hole is M8 which can be drilled out up to M10 diameter. The sensor can be connected to a PLC or to a hazard monitoring system, such as 4B’s T500 Hotbus Elite, Watchdog Super Elite, or T400 Elite. The connections are not polarity sensitive therefore special connections requirements are eliminated. The WDB7 series is approved for use in ATEX and IECEx Zone 20 dust hazard locations.

WDB Series Bearing Sensors

The WDB series bearing sensors are designed to screw directly into a bearing housing. Each sensor is fitted with a grease zerk to allow lubrication of the bearing without the need for removal of the sensor.

The WDB8 series have a 1/4” BSPT thread. The WDB2 series have a 1/8” NPT thread. Three versions are available; an NTC thermistor or Pt100 RTD type for continuous temperature monitoring, and a PTC thermistor model with the following trip points (specify when ordering): 60°C, 70°C, 80°C, 90°C for step (Cold/Hot) temperature monitoring.

The sensor is supplied with a three meter attached cable and can be connected to a hazard monitoring system, such as 4B’s T500 Hotbus Elite, Watchdog Super Elite, or T400 Elite or to a PLC. The connections are not polarity sensitive therefore special connection requirements are eliminated, and the cable can be extended in the field.

Videos

Design Services

Hazard Monitoring Design Service

Hazard Monitoring Design Service

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.