REF 70™ 斗提机畚斗螺栓等级为 ISO 5.8 级,螺栓头一面呈现圆弧形曲面,另一面上带有 4 个对置的凸点,凸点的作用是拧紧螺栓时防止转动。REF 70™ 畚斗螺栓配合大椭圆垫使用时,最适合安装皮带轮直径大于 50 厘米的重工业钢制畚斗。因为这种螺栓有圆弧形的曲面,这种螺栓不适合安装后背平直的塑料畚斗,尤其不适用薄皮带。

Specifications

| Ref70 | Size | Size | Head Diameter | Max. Torque | Package Quantity | Package Weight |

| (mm) | (in.) | (mm) | (Nm) | (kgs) | ||

| M6 x 12 | 1/4 x 1/2 | 17 | 5 | 100 | 1.04 | |

| M6 x 20* | 1/4 x 3/4 | 17 | 5 | 100 | 1.18 | |

| M6 x 25* | 1/4 x 1 | 17 | 5 | 100 | 1.24 | |

| M6 x 30 | 1/4 x 1-1/4 | 17 | 5 | 100 | 1.48 | |

| M6 x 40 | 1/4 x 1-1/2 | 17 | 5 | 100 | 1.56 | |

| M8 x 20 | 5/16 x 3/4 | 23 | 10 | 100 | 2.08 | |

| M8 x 25* | 5/16 x 1 | 23 | 10 | 100 | 2.38 | |

| M8 x 30* | 5/16 x 1-1/4 | 23 | 10 | 100 | 3.54 | |

| M8 x 40* | 5/16 x 1-1/2 | 23 | 10 | 100 | 2.90 | |

| M8 x 50 | 5/16 x 2 | 23 | 10 | 100 | 3.24 | |

| M10 x 25 | 3/8 x 1 | 27 | 18 | 100 | 3.94 | |

| M10 x 30* | 3/8 x 1-1/4 | 27 | 18 | 100 | 4.44 | |

| M10 x 40* | 3/8 x 1-1/2 | 27 | 18 | 100 | 4.80 | |

| M10 x 45* | 3/8 x 1-3/4 | 27 | 18 | 100 | 5.08 | |

| M10 x 50* | 3/8 x 2 | 27 | 18 | 100 | 5.36 | |

| M10 x 55 | 3/8 x 2-1/4 | 27 | 18 | 100 | 5.50 | |

| M10 x 65 | 3/8 x 2-1/2 | 27 | 18 | 100 | 5.72 | |

| M12 x 30 | 1/2 x 1-1/4 | 35 | 42 | 100 | 7.44 | |

| M12 x 40 | 1/2 x 1-1/2 | 35 | 42 | 100 | 7.78 | |

| M12 x 45 | 1/2 x 1-3/4 | 35 | 42 | 100 | 8.12 | |

| M12 x 50 | 1/2 x 2 | 35 | 42 | 100 | 8.44 | |

| M12 x 55 | 1/2 x 2-1/4 | 35 | 42 | 100 | 9.08 | |

* Available in stainless steel

Accessories

大椭圆垫

配合 REF70 螺栓用于重载环境

- 镀锌或 304 不锈钢

- 座在 REF70 螺栓头的 4 个凸点上,增加螺栓头的有效接触面积和螺栓的抓握力

- 要用大椭圆垫,皮带必须有足够的厚度接纳垫圈,以及/或者畚斗螺栓孔必须有圆弧形凹陷

- 皮带轮直径小于 500 毫米不推荐使用大椭圆垫片

- 大椭圆垫圈长轴方向平行于运动方向

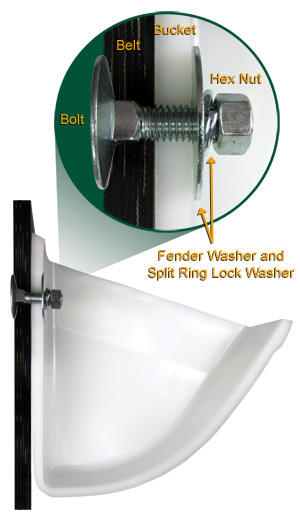

Elevator Bolt Hardware

Along with the various types and sizes of elevator bolts, 4B offers all of the hardware required for each fastener.

For more information on all elevator bolt hardware specifications, see our full bolt catalogue by clicking the link below.

FAQ's

Is the installation of Ref70 bolts any different to other elevator bolts?

When using the large Reference 70™ (REF 70™) oval washer with the REF 70™ bolt, the washer should be placed with the widest part across the belt in order to minimize stress on the system as it passes around the curved pulley.

Note: the bolt head and oval washer are installed on the back of the belt.

FAQ - Elevator Bolts

How long of an elevator bolt do I need?

When installing buckets on an elevator belt, use this simple formula:

(belt thickness + bucket back thickness + washer thickness + nut thickness + 1/4 inch)

What grade are 4B elevator bolts?

4B elevator bolts meet or exceed ISO Grade 5.8 / SAE Grade 2 standards. The bolt grade guide below is for bolt diameters of 6mm (1/4") to 12mm (1/2"):

BOLT GRADE GUIDE:

| ISO Grade | SAE Grade | Min. Tensile Strenghth (psi) |

|---|---|---|

| 5.8 | 2 | 74000 |

| 8.8 | 5 | 120000 |

| 10.9 | 8 | 150000 |

What torque setting should I use?

An ideal installation will result in the elevator bolt head fitting snuggly just below the surface of the belt after tightening (Image B). However, never exceed the maximum recommended torque as shown in the tables below:

MAXIMUM RECOMMENDED TORQUE FOR 4B ELEVATOR BOLTS METRIC ISO GRADE 5.8

| Bolt Dia. | in. lbs. | ft. lbs. | nm |

|---|---|---|---|

| M6 | 72 | 6 | 8 |

| M7 | 115 | 10 | 13 |

| M8 | 168 | 14 | 19 |

| M10 | 336 | 28 | 38 |

| M12 | 588 | 49 | 66 |

MAXIMUM RECOMMENDED TORQUE FOR 4B ELEVATOR BOLTS SAE GRADE 2 OR 302 STAINLESS STEEL

| bolt dia. | in. lbs. | ft. lbs | nm |

|---|---|---|---|

| 1/4" | 72 | 6 | 8 |

| 5/16" | 156 | 13 | 18 |

| 3/8" | 276 | 23 | 31 |

| 1/2" | 684 | 57 | 77 |

How do you install an elevator bolt?

The head of the elevator bolt should lie against the inside surface of the elevator belt with the nuts and washers on the inside of the elevator bucket. An ideal installation will result in the elevator bolt head fitting snuggly just below the surface of the elevator belt.

Do you have any maintenance recommendations?

After initial installation, it is recommended that the bucket elevator be run for approximately four hours. After which the bolts should be re-tightened to ensure that there are no loose parts. Periodic inspections are always recommended to check for any issues that may occur during the life of the elevator, including checks for loose or damaged elevator bolts.

Design Services

斗提机设计服务

斗提机设计服务

4B 迄今为止已为各行各业设计了数百种斗提机,包括动物饲料、粮食储运加工、面粉加工、麦芽酿酒行业到水泥、煤炭和其他重工业。

得益于 4B 的深厚技术储备和全球范围的广泛应用经验,我们的工程师精于计算设计各种斗提机。只要您能提供关键指标,我们的工程师就能为您提供详细的设计细节,达到最理想的生产能力和卸料特性。我们既可以为您设计全新的斗提机系统也可以改造提升现有的斗提机系统,达到节能降耗,提高效率的目的。

获得免费的斗提机计算数据

为了我们能更有效地处理您的需求,请尽可能准确地输入这个表格里的各项参数。

4B 迄今为止已为各行各业设计了数百种斗提机,包括动物饲料、粮食储运加工、面粉加工、麦芽酿酒行业到水泥、煤炭和其他重工业。

得益于 4B 的深厚技术储备和全球范围的广泛应用经验,我们的工程师精于计算设计各种斗提机。只要您能提供关键指标,我们的工程师就能为您提供详细的设计细节,达到最理想的生产能力和卸料特性。我们既可以为您设计全新的斗提机系统也可以改造提升现有的斗提机系统,达到节能降耗,提高效率的目的。

获得免费的斗提机计算数据

为了我们能更有效地处理您的需求,请尽可能准确地输入这个表格里的各项参数。