The Milli-Speed Sensor has a 4-20 mA output proportional to calibrated speed, it is designed to allow detection of belt slip & underspeed, stop motion, low speed or zero speed on bucket elevators, conveyors, airlocks, mixers, fans, grinders and many other rotating machines. Totally sealed and simple to calibrate, the Milli-Speed works in the harshest of conditions.

An inductive sensing device located in the nose of the Milli-Speed enclosure will detect a metal target. This target can be an existing bolt head or device attached to a shaft, such as 4B’s Whirligig® sensor mount. During installation, the Milli-Speed is set to the normal running RPM by simple magnetic calibration.

- 4 - 20 mA Output

- Simple Magnetic Calibration

- Loop Powered (2 Wire)

- Totally Sealed Construction: Submersible

- Built In Conduit Adaptor (1/2” NPT)

- Easy Installation with Whirligig® Sensor Mount

- SpeedMaster™ Compatible for Accurate Testing

Belt Conveyor

Bucket Elevator

Downloads

Accessories

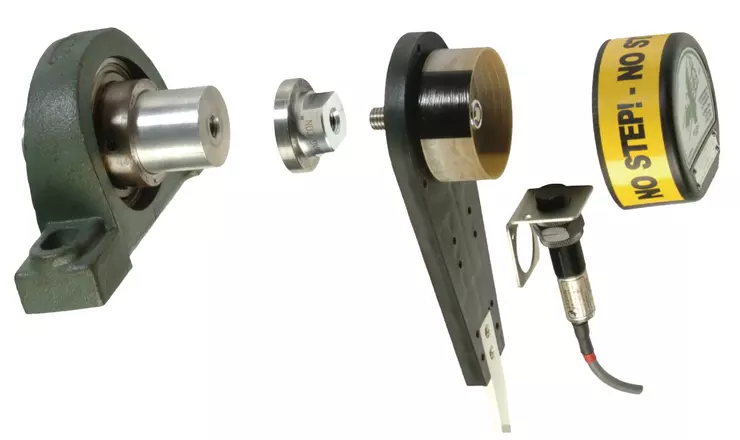

SpeedMaster™

The SpeedMaster™ with Pulse Pilot is the only device that accurately tests the calibration of a speed switch, and allows testing of the 10% alarm and 20% shutdown features of the sensor while installed on the machine shaft.

The SpeedMaster™ operates in two modes. Input mode is used to measure the pulse rate at normal speed. Output mode will allow the user to simulate belt underspeed for testing purposes.

The Pulse Pilot fits between the gap between the sensor and the target. The Pulse Pilot will have no effect on the operation of the speed switch until it is connected to the SpeedMaster™ and set to Output mode.

Whirligig®

The Whirligig® is a fully guarded target for easy mounting of motion sensors. It is a universal shaft sensor mount suitable for all industry standard cylindrical or DIN style inductive sensors including 4B's M100, M300, and M800 speed switch sensors.

The sensor bolts to the Whirligig base plate and the complete assembly either bolts to the machines shaft through a M12 tapped hole, or is connected magnetically using 4B’s patented Mag-Con™ adaptor. Shaft or machine vibration does not affect the performance of the sensor, as the whole assembly moves with the shaft. With the Whirligig, installation of speed sensors is now simple, safe and reliable.

4B Sensor Mounting Kit

The 4B Sensor Mounting Kit is able to securely mount barrel sensors in position, including 4B’s range of 18 & 30mm wide inductive sensors.

Made of Stainless Steel and Nylon 66, giving corrosion resistance as well as abrasion resistance and high melting points, the brackets are ideal for harsh environments.

A flexible mounting head and foot can be rotated independently before being locked in the required position using the supplied screws.

4B Speed Relay (USR)

The Speed Relay is a microprocessor controlled digital speed monitor for use with 2, 3, 4 wire NPN/PNP sensors, 4B’s WDA range of sensors or Contact sensor inputs, with a user programmable electromechanical relay and PhotoMOS Solid State Relay (SSR) outputs. The Speed Relay has a 160x80 pixel LCD display to provide information, and 3 front panel buttons to program settings.

Monitors

IE-Node

The Industrial Ethernet Node (IE-NODE) is a remote monitoring interface designed to provide sensor data to PLC’s or other automation and control systems.

Both units can be expanded to 16 sensor inputs with the installation of optional expansion boards.

The IE-NODE operates by reading its sensor inputs and sending processed data when requested by another system (e.g. PLC). The units are equipped with an RJ45 Ethernet socket and supports PROFINET, EtherNet/IP and Modbus TCP/IP protocols for easy integration with Siemens, Allen-Bradley Rockwell, Modicon and other PLC’s or automation devices.

The IE-NODE’s network configurator software provides a visual view of all devices on the network. It allows for easy identification of each unit on the network and allows for network settings to be changed as needed.

FAQ's

What voltage is needed for the Milli-Speed?

The Milli-Speed is looped powered and requires 17 - 30 VDC.

How do you calibrate the Milli-Speed?

The Milli-Speed is calibrated with a magnetic using the calibration point on the front of the sensor, please refer to the

operation manual for details.

Why is the Milli-Speed not working when mounting to the Whirligig?

There are two sets of holes in the base plate of the Whirligig, be sure to use the top holes to mount the Milli-Speed flush to the Whirligig guard and target.

Videos

Design Services

Hazard Monitoring Design Service

Hazard Monitoring Design Service

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.